WELCOME TO

Advanced IC Engineering, Inc

Hardware and Software Engineering Services

Updated May 2024

We do not provide service or products to New York State.

PRODUCTS & SERVICES

Advice provides hardware and software solutions in many packages. We have a very strong background in communications, digital and analog design. We cover both embedded and system software.

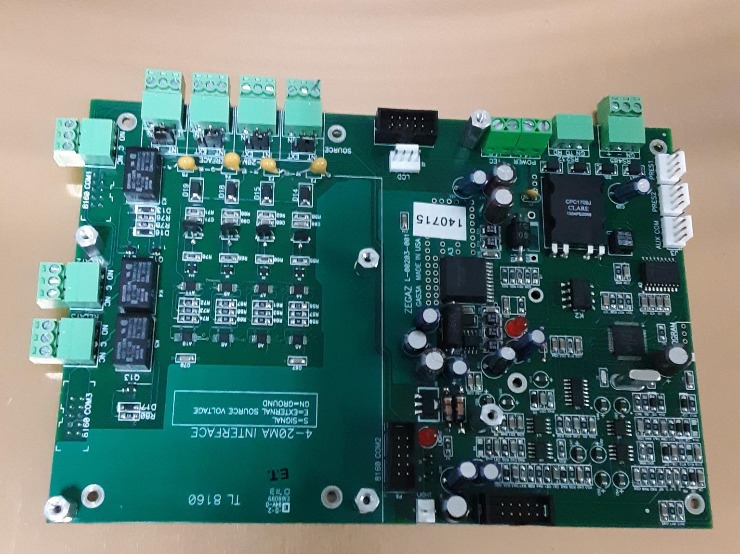

Example of one of our system designs

This product was designed for Zegaz Insturments to work with their Hydrocarbon Dewpoint Analysis System (HCD-5000). It couples to a microcomputer provides RS232, RS485, 4-20mA, Modbus, TCPIP GUI, User Relays as well as operate the patented dewpoint cell.

CONTACT US

Call or email us with any questions you may have.

We receive a lot of email and it is easy to get filtered out, so place in the subject line "Inquiry or RFQ"

410-259-9941

info@advice1.com

Projects@advice1.com

If you have a potential project send the files to this address and give us a call at

410-259-9941.